In every way, Big B’s Fabulous Juices is a family business. The organic juice plant was founded more than 40 years ago by Bernie Heideman and his wife, in a historic 110 year-old fruit packing shed along the railroad tracks in Hotchkiss. Under Schwartz family ownership since 2002, Big B’s has increased its juice processing from 500,000 pounds of apples a season to 4,000,000. Yup, that’s right, four million pounds of apples a season.

The math staggered me. I had arrived to interview Jeff Schwartz at the end of an especially long cold day. He was moving apple bins with a forklift, and when he finished he waved at more bins full of every color apple. “We’re up this year from three thousand bins to over four thousand,” he said. “A thousand pounds of apples in each bin, and ninety percent of them are grown here in the North Fork Valley.”

Jeff and his wife Tracey, his brother, and his father, are the major stakeholders in the business, which is a significant contributor to the North Fork economy, and this year just won “Hotchkiss Business of the Year.” Big B’s employs several extended families and buys apples from more than a dozen small, medium and large orchards in the valley. Four million pounds of apples!

“In ten years, we have just grown to the scale that we knew we’d be able to deal with the following year. It’s been a pretty good moderate paced growth, while keeping the product to superior standards, and that’s what keeps us alive. Because if we ever tried to compete with the mediocrity of a commercial product, we’d get killed.”

Jeff acknowledges that his locally sourced, organic cold-pressed cider costs a little bit more than commercial cider, but says they try to price wisely. “If you want to take a gallon of cider home for eight dollars, it’s probably worth it when you figure it takes four people a week to drink it.” No wonder: It takes more than forty apples to create a gallon of Big B’s apple cider. That’s ten organic apples a week per person in a four-person family. That’s healthy!

We stepped out of the crisp afternoon cold and into the dimness of one of the newer buildings to begin our tour. He showed me where the bins are dumped and apples get sorted and washed, and then the juicing line and bottling lines. In this loud bright room, giant bags of jugs and gleaming tanks stand waiting to be filled as people move apples through the process of getting ground into pumice and then squeezed into juice.

We stepped out of the crisp afternoon cold and into the dimness of one of the newer buildings to begin our tour. He showed me where the bins are dumped and apples get sorted and washed, and then the juicing line and bottling lines. In this loud bright room, giant bags of jugs and gleaming tanks stand waiting to be filled as people move apples through the process of getting ground into pumice and then squeezed into juice.

“We juice all day long, about 40 bins a day, pressing from 7 or 8 a.m. til 4 o’clock, from September through February, filling tanks as we go,” Jeff says over the din of the grinding and juicing machines. The leftover pulp shoots from the end of the line through a chute to the outside, straight into a waiting 40-yard dump truck. “This closes the loop,” Jeff says enthusiastically. “We fill this once a week and sell it to a local compost maker, and then we use some of that compost in our orchards.”

Until recently, Big B’s Cold Pressed Apple Cider has been preserved with an ultraviolet process, which is “the best way to keep the taste and nutrients of raw unpasteurized cider,” and gives it a 14-day shelf life; the juice line has been thermally pasteurized, giving those flavors a 12-month shelf life. This year, Jeff explains, they’re also trying a new high-pressure technology from a company in Boulder, allowing them to offer a “cool new product line” of fresh, uncooked juices with a 75-day shelf life.

No preservatives or sugars are added to the products, which come in a mouthwatering assortment of flavors. The cold-pressed apple cider comes in regular and spiced, and is only available during the pressing season. Jeff suggests if you want fresh cider some other time during the year, you drink a little off the top of the bottle and freeze the rest, which is then good for a week after you thaw it. He also explains that all their products use a blend of sweet and tart apples, and that the exact flavor of the cider will vary a little throughout the season according to which of the thirteen apple varieties (Rome, Fuji, Jonagold, Honeycrisp, Gala, etc.) are ready at that time.

No preservatives or sugars are added to the products, which come in a mouthwatering assortment of flavors. The cold-pressed apple cider comes in regular and spiced, and is only available during the pressing season. Jeff suggests if you want fresh cider some other time during the year, you drink a little off the top of the bottle and freeze the rest, which is then good for a week after you thaw it. He also explains that all their products use a blend of sweet and tart apples, and that the exact flavor of the cider will vary a little throughout the season according to which of the thirteen apple varieties (Rome, Fuji, Jonagold, Honeycrisp, Gala, etc.) are ready at that time.

Besides the fresh cider, Big B’s website displays six flavors of organic apple juice, including cherry apple, pear apple, ginger apple, spearmint apple and apricot apple; and several other organic or all-natural beverages: lemonade, hibiscus pomegranate lemonade, spearmint lemonade, black iced tea, and, in a nod to Big B’s founder, the Bernie Palmer, half iced tea and half lemonade.

“Right now,” Jeff says, “We plan to hold Big B’s where we are now; from an energy perspective it doesn’t make sense to try to expand too much farther out. Our market is pretty saturated now from Ft. Collins to Albuquerque, with spokes east toward Omaha and west through Utah. If we can get the sales we want from being truly bioregional, it’s so much better. The fruit’s better and so’s the process, so much more efficient and more profitable, with minimum impact.”

Every aspect of Big B’s takes into account environmental impact, from this bioregional ethic to their choice of HDPE plastic bottles rather than glass, calculating a carbon footprint based on the best, healthiest and most environmentally friendly choices they can make for their methods and their customers.

Every aspect of Big B’s takes into account environmental impact, from this bioregional ethic to their choice of HDPE plastic bottles rather than glass, calculating a carbon footprint based on the best, healthiest and most environmentally friendly choices they can make for their methods and their customers.

“From the supply side,” Jeff says, “we have a very strong place. It’s an industry just based around moving the apples and the liquids. Hard cider is the wave of our future. It’s even more profitable because it’s value-adding to Big B’s. It’s truly the most efficient and sustainable localized alcohol, it’s apples.”

He adds, “The biggest acreage of western slope fruit is right here in the North Fork Valley. White Buffalo, Ela Family Farms, First Fruits, and other orchards. Rogers Mesa Fruit makes viable the fruit industry here, because without a packing shed you’re had.” Big B’s gets apples from some of the larger organic orchards in the valley and also mid-size and backyard orchards.

“Whoever has apples, we buy them,” he says. “Small backyard producers who have the ability to pick their eight or ten trees and get us a couple of bins, we’ll buy them. If people have a tractor and a loader that’s great. If we can support people to take care of their trees that’s good. The next size orchard up, 50-100 bin places, there are probably four or five, then there are probably about six big producers that are small in the big picture, but big for us here. Even our biggest orchards can’t compare in size to those in Washington State.”

By now we have moved into the fermentation room, where Big B’s apples transform in the hands of skilled brewer Shawn Larson into five flavors of hard cider sold under the North Fork Cellars label: Orchard Apple, Sweet Peach, Pear Hill, Cherry Days, and Winter Spiced.

“The traditional method that we’ve worked with these products so far,” Jeff says, “has been to ferment different types of apples singularly and then blend them later after a few months of fermentation and aging. Now, we have the tanks to add fresh juice which adds sugar and carbonation. The next step for this label is to carbonate in a tank and try to figure out as we introduce this product into the Colorado market, what’s a good drinkable, proper cider?” But, he adds, “Winesap apples make the finest ciders we’ve made.”

I mention an article I read which suggests that hard cider is the new micro-brew, and Jeff replies with a yeah-but-not-quite shrug. “Micro-brews took off because there was already a huge culture of beer drinkers. Cider, while coming from a place of tradition in this country, well, we just don’t have that kind of existing cider culture” that could transition quickly to micro-brew hard ciders. But, he adds, “The cider business is really starting to take off.”

I mention an article I read which suggests that hard cider is the new micro-brew, and Jeff replies with a yeah-but-not-quite shrug. “Micro-brews took off because there was already a huge culture of beer drinkers. Cider, while coming from a place of tradition in this country, well, we just don’t have that kind of existing cider culture” that could transition quickly to micro-brew hard ciders. But, he adds, “The cider business is really starting to take off.”

“Our focus now is to supply our tasting room, feeding our home base,” he says happily. “Anything bigger than that is gravy. Our ciders are getting more mature and better as we start to learn more about it. It’s a fun little alcohol, it’s light… a fun little buzz.”

And he proves that to me later. First, though, we pass through a small storefront that housed an early Big B’s retail outlet, and now serves a strong purpose for the Mexican community here, providing contemporary and traditional Mexican food and household products, phone cards, and other amenities that gratify his employees and the wider Mexican-American population of the valley.

Then we descend into the cellar, a low-ceilinged room with a concrete floor, filled with barrels and crates of various apple products. Throughout the tour we have continually passed by palettes of crates of ciders and juices and pallets of apples, and inhaled subtly shifting aromas through the different rooms. Jeff keeps a running commentary about his plans for improvements to further grow and streamline the business. “We’re also experimenting with biodynamic preparations being made here in this valley and then returning that to the soil, inoculating our places with true life force.” I’m fascinated but I get too cold in the cellar to pay attention.

Then we descend into the cellar, a low-ceilinged room with a concrete floor, filled with barrels and crates of various apple products. Throughout the tour we have continually passed by palettes of crates of ciders and juices and pallets of apples, and inhaled subtly shifting aromas through the different rooms. Jeff keeps a running commentary about his plans for improvements to further grow and streamline the business. “We’re also experimenting with biodynamic preparations being made here in this valley and then returning that to the soil, inoculating our places with true life force.” I’m fascinated but I get too cold in the cellar to pay attention.

We wind up in the employee break room, where we settle into chairs with a couple of bottles of hard cider and two paper cups between us, as we relax from interview into conversation.

Jeff and his wife Tracey moved to the valley from Flagstaff in 2000, after trying for awhile there to farm in the Arizona desert. They had come together at a permaculture workshop, while he was working on the Navajo Reservation learning basic farming skills, and she lived in the Bay Area. Both were involved in environmental and social activism before and after their marriage, but after awhile, he says, “We knew we wanted to farm and not just be running around fighting. If I didn’t have to pick up arms I wasn’t going to fight a political battle. So that’s what we got to do, that’s our way of fighting. We want to give our kids a small skill set and the confidence and ability to survive. That’s what drives everything we do, those two kiddos.”

After a short stint farming asparagus on Sunshine Mesa, they met the Heidemans, and soon began working for them at Big B’s. After their second season there, Bernie suggested they buy the place, so he and Tracey talked with his brother and dad about the investment and decided, “Let’s go down that road of permanence here. I couldn’t be more grateful to Bernie for giving us the opportunity to do it. It’s our family now,” he says. “It’s the four of us, the ten of us, the twenty of us. Everybody has their part.”

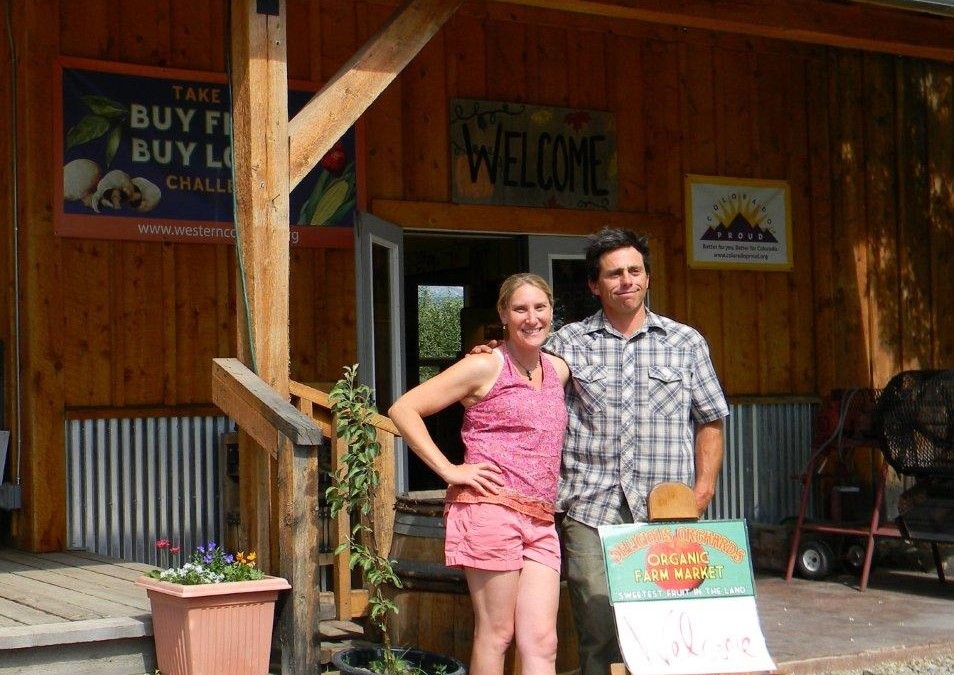

Jeff and Tracey also own Delicious Orchards in Paonia. They bought Delicious a few years after they got settled into Big B’s, when an employee came to him and said there was an orchard he was interested in buying, and would Jeff buy the fruit. The timing was right and the location on the highway perfect for retail, and they already had the product. The employee lost interest, but the Schwartz family moved on the deal, and acquired a sixteen-acre organic orchard with a big bare building.

Jeff and Tracey also own Delicious Orchards in Paonia. They bought Delicious a few years after they got settled into Big B’s, when an employee came to him and said there was an orchard he was interested in buying, and would Jeff buy the fruit. The timing was right and the location on the highway perfect for retail, and they already had the product. The employee lost interest, but the Schwartz family moved on the deal, and acquired a sixteen-acre organic orchard with a big bare building.

Over the years, they’ve transformed that shed into a delightful farm store offering Big B’s products, great local organic foods including cheese and seasonal vegetables, and local arts, crafts and books. A tasting bar refreshes visitors with Big B’s hard ciders as well as many local wines. Tracey is an ace knitter, and a small wall of the store overflows with a rainbow of fine yarns. A café serves food made from local ingredients, and a campground nestled in the orchard boasts views of the surrounding mountains. Saturdays in summer often host an all-day barbecue with live local music, and for a small membership fee, members get a 5% store discount and monthly specials.

Throughout fruit season, Delicious Orchards sells their own organic fruits and is a popular U Pick destination for locals and travelers alike. This family-friendly activity is a lot of fun for everyone, with low limbs for kids and ladders throughout the orchards for the more adventurous. It’s a great way to spend a few hours and come home with a bounty of fresh cherries, pears, peaches or apples, depending on what’s ripe for the picking.

Throughout fruit season, Delicious Orchards sells their own organic fruits and is a popular U Pick destination for locals and travelers alike. This family-friendly activity is a lot of fun for everyone, with low limbs for kids and ladders throughout the orchards for the more adventurous. It’s a great way to spend a few hours and come home with a bounty of fresh cherries, pears, peaches or apples, depending on what’s ripe for the picking.

In addition to Delicious, the Schwartzes are responsible for several other orchards in the valley. “Moving forward,” says Jeff, “if we can grow as much fruit as possible that’s a real key to our success. With this traditional economy in the North Fork, you make money when you have fruit. There’s going to be years when you don’t get any, from early freezes, or late hails, but when you do, it’s money that grows on trees.”

For this east coast urbanite who grew up roaming New York City end to end, Jeff Schwartz shows a remarkably grounded tenderness for the earth. “We have a lot of microclimates in the North Fork Valley that allow agriculture here. It’s one of the premier places here on this planet to inhabit, if you think about our climate and our soils and our cover and everything we have, our ability to take water out of the mountains, it’s a sweet valley. And it’s also the people that have been here, and the beauty of it. I hope all these small farmers continue to be happy with the few bucks that they make, because that’s all we can really expect to make.”

We come inevitably to the topic on everybody’s minds, industrial development in this agricultural promised land. Jeff says, “Yeah, higher intensity fracking of the valley… Wouldn’t it be a shame if what we don’t know about it does negatively affect this bottomland, this place for habitation and growing food for a small but greater bioregion? We have to pray that it might not… If they don’t find pockets of it, then we’re safe; if they find pockets of it, maybe we can slow it down and make it more appropriate. I don’t know. I believe in this place and in the people of this place, and the historical and ancient value of this place. I believe we will fend it off. Because of the experience and the sacrifice of people elsewhere that have suffered from it, we’ve learned a lot.”

We come inevitably to the topic on everybody’s minds, industrial development in this agricultural promised land. Jeff says, “Yeah, higher intensity fracking of the valley… Wouldn’t it be a shame if what we don’t know about it does negatively affect this bottomland, this place for habitation and growing food for a small but greater bioregion? We have to pray that it might not… If they don’t find pockets of it, then we’re safe; if they find pockets of it, maybe we can slow it down and make it more appropriate. I don’t know. I believe in this place and in the people of this place, and the historical and ancient value of this place. I believe we will fend it off. Because of the experience and the sacrifice of people elsewhere that have suffered from it, we’ve learned a lot.”

Discussions of air quality and water contamination crop up wherever two or three valley residents get together. We cover these, and more, and Jeff mentions the size of the trucks he’s seen occasionally in convoy down the highway. “Highway 133 is not sufficient to support that kind of traffic. Those trucks I’ve seen driving down the highway, those nine trucks in a row, and the unbelievable size of them. We just can’t handle that impact on our roads.” And like many in the valley, Jeff is ready to turn his concern into action when it comes to protecting the North Fork. Jeff was among a delegation that traveled from the area to Washington DC in June 2013, to bring the case to federal decision-makers that some places were more valued for their other resources than to be turned into an oil or gas field.

By now, half the hard cider is gone from the bottles. They must have holes in them somewhere. Big B’s employees start to trickle through the break room on their way home for the day. Jeff greets them all by name, “Bye, see you tomorrow, thanks!” And they respond in kind with smiles and waves. There is an ease of being, a family feel, during this end of the day ritual.

Jeff has a lot more work to do before he can head home to his family, so I pack up and we head outside. He loads me up with a couple of bottles of North Fork Cellars hard cider, and a half gallon of Big B’s Cold Pressed Apple Cider, along with instructions on how to ferment it myself at home. I know the cider won’t last long enough for me to try that, but I listen anyway, watching alpenglow settle over Mt. Lamborn and enjoying that mild sense of well-being from the refreshment in the break room.

Jeff has a lot more work to do before he can head home to his family, so I pack up and we head outside. He loads me up with a couple of bottles of North Fork Cellars hard cider, and a half gallon of Big B’s Cold Pressed Apple Cider, along with instructions on how to ferment it myself at home. I know the cider won’t last long enough for me to try that, but I listen anyway, watching alpenglow settle over Mt. Lamborn and enjoying that mild sense of well-being from the refreshment in the break room.

I remark upon how hard he must work as the main man in this thriving fruit growing and processing operation. Jeff’s reply sums up his motivation and inspiration:

“I am driven because it’s a blessing and a dream. I dreamed this when I was nine or ten years old, helping my dad with the tomato plants on the porch. To realize it… is just so amazing. Things are good, things are as good as we could ever expect or want.”

Big B’s Mission Statement

“Our mission is to make the highest quality, best tasting, local and organic juices and beverages. Our aim is to support sustainable agriculture while having a positive impact on our customers, our vendors, our employees, our community, and our families.”

About the parties, Trump wants less gov regulation for businesses (which stifles family farms–a local long-time family farm/ orchard is selling out because of the “straw that broke the camel’s back”–within 2 yrs they would have to put a water treatment plant in for their irrigation pond!!!!! How about just stop letting farmers feed antibiotics and roundup-laden feed to their animals (which creates antibiotic resistance) and teach consumers to wash their food and cook meat right!? Put responsibility where it belongs, instead of ruining the small farmer, while the giant mega farms can afford all the regs because if scale– and they are usually the reasons for recalls!

Anyway–we had some

small bottles of your organic cherry apple juice and loved it! Got it at a local greenhouse in Newburg, PA. Please don’t say it was a fluke and we won’t be able to get it again! ?????

This would be a travesty to have fracking in your beautiful valley. I believe this is a very bad thing and hope that your bit of heaven is not tainted in any way. Water is wonderful there

and everything thrives. They must stop this devastation of our country.